The car manufacturing industry has undergone significant changes in recent years due to the integration of robotics technology. Robotics has enabled manufacturers to improve the speed, efficiency, and precision of their production processes, while also increasing safety for workers.

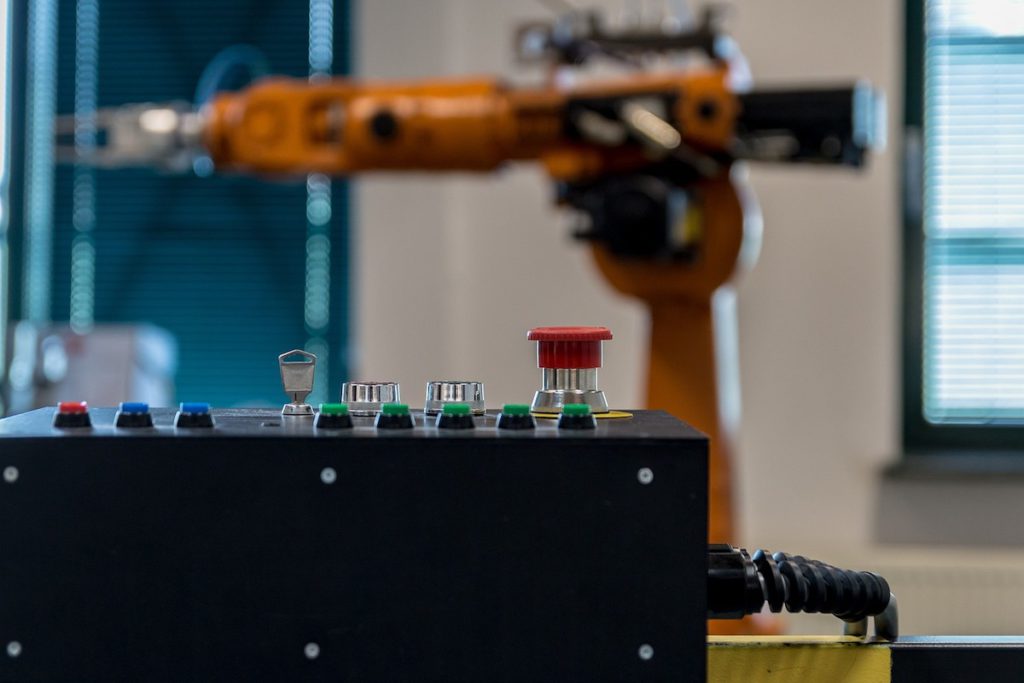

One of the critical ways robotics is used in the car manufacturing industry is through robotic arms on the assembly line. These robotic arms can perform various tasks, such as welding, painting, and handling heavy parts. By automating these tasks, manufacturers can produce cars faster and more accurately than ever. Additionally, robotic arms can work continuously, allowing for increased production capacity.

Another way robotics is changing car manufacturing is by using autonomous guided vehicles (AGVs) to transport materials and components around the factory. AGVs can navigate the factory floor independently, reducing the need for human operators to move materials and components. This not only improves the speed and efficiency of the production process but also reduces the risk of accidents or injuries on the factory floor.

Furthermore, Robotics sensor systems and machine learning techniques are being increasingly utilized in the car manufacturing industry. The sensor system can be used in quality checks, and measurements to predict and prevent equipment failures. Machine learning techniques enable robots to adapt to different tasks, increase flexibility, and improve production efficiency.

Robotic technology has brought many benefits to the car manufacturing industry, from increased speed and accuracy to improved safety for workers. Furthermore, integrating robotics technology allows manufacturers to produce high-quality vehicles faster and more efficiently.